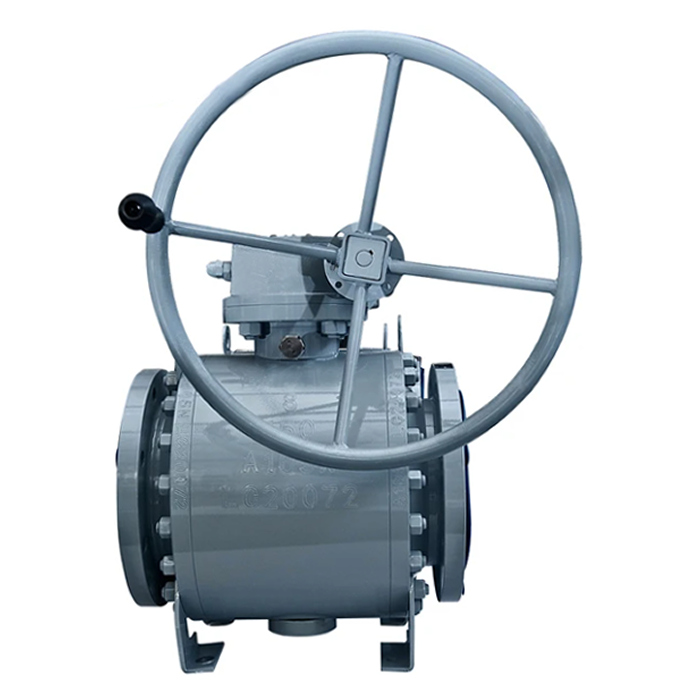

Side Entry Trunnion Ball Valve

A side-entry trunnon ball valve is a type of trunnon-mounted ball valve where the ball is assembled from the side.

The body is made of cast or forged steel with construction comes in 2 or 3-pieces depending on the size and class.

The combination of trunnion-mounted balls and unique spring-loaded upstream sealing provides bubble-tight shut-off and low operating torques, even at extremely high shut-off pressure.

Side-entry trunnion ball valves are the standard ball valve type and should be the default choice for general service.

General Features and Benefits

- Standard double block sealing performance: each seat blocks the flow from each side.

- Cavity over-pressure self-relieving: Over-pressure in the body cavity will pop the seats off the ball surface, and excess pressure will be relieved into the pipeline. After the pop-off action, the seats will return to their normal position, in contact with the ball.

- Body and bonnet sealing: gasket and O-ring seal to guarantee the sealing performance at high and low pressure conditions.

- Leakage rate: ISO 5208/EN 12266-1 Rate A (zero visual leakage)

- Fire-safe design to API 607/API 6FA

- Anti-static design: A static conduction spring is used as standard between the stem and the ball.

- Anti-blow-out stem

- Low-operation torque design

Options

- Fully welded ball valve

- Double piston effect seat (DIB-1, DIB-2)

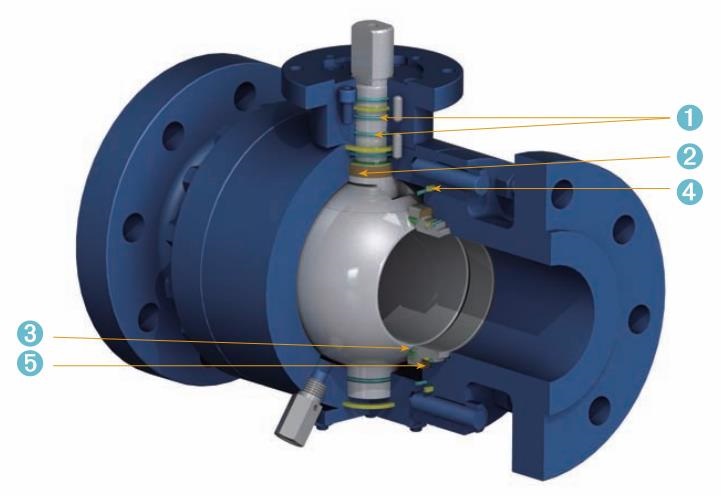

Design Features

Forged Steel Trunnion Mounted Ball Valves

① Two O-ring seals prevent leakage from the stem area.

② Blow-out-proof stem: a safety feature that functions to assure stem sealing at all pressures.

③ Back-up metal-to-metal Sealing: When primary soft-seat material is deteriorated by fire, the metal-to-metal seat provides shutoff.

④ O-ring and Gasket Combination: Prevents leakage from the body connection area.

⑤ Floating spring-loaded seats: ensure sealing even at low pressures.

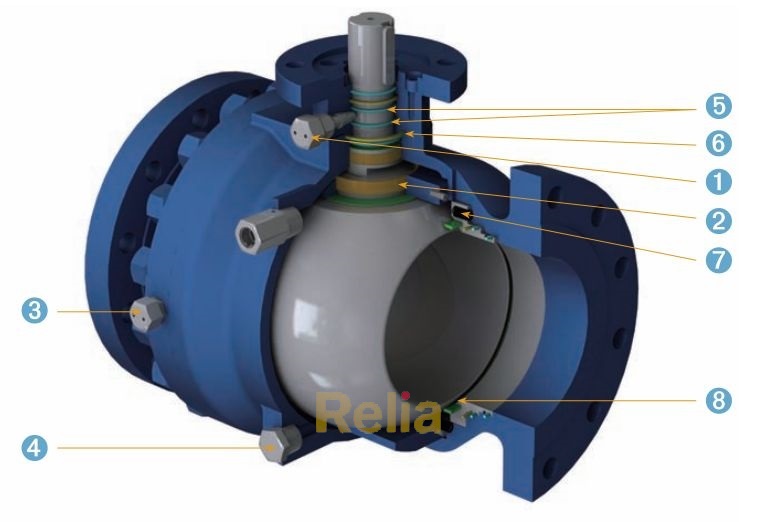

Cast Steel Trunnion Mounted Ball Valves

① Emergency Sealant Injection Fitting: Prevents leakage from the stem.

② Blow-out Proof Stem: Stem functions as the backseat to assure stem sealing at all pressures.

③ Emergency Sealant Injection Fitting: Prevents leakage from the seat.

④ Drain plug:Relieves the body cavity.

⑤ Double Sealing O-rings:Prevents leakage from stem area.

⑥ O-ring & Gasket Combination:Prevents leakage from body connection area.

⑦ Floating Spring: Loaded seats assure sealing, even at low pressures.

⑧ Metal-to-Metal Sealing: When soft seals are deteriorated by fire, seat float to shut of the line fluid.

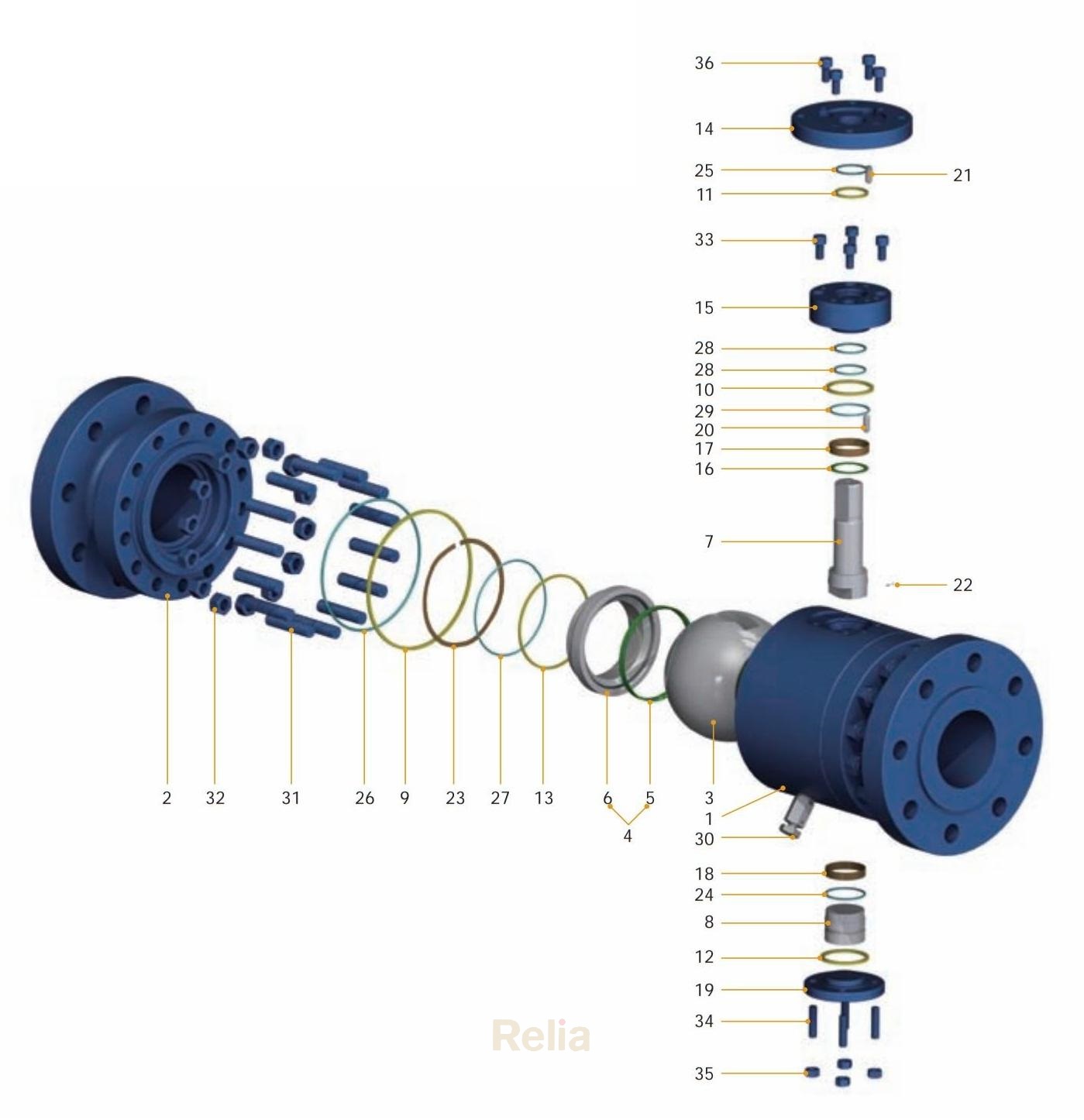

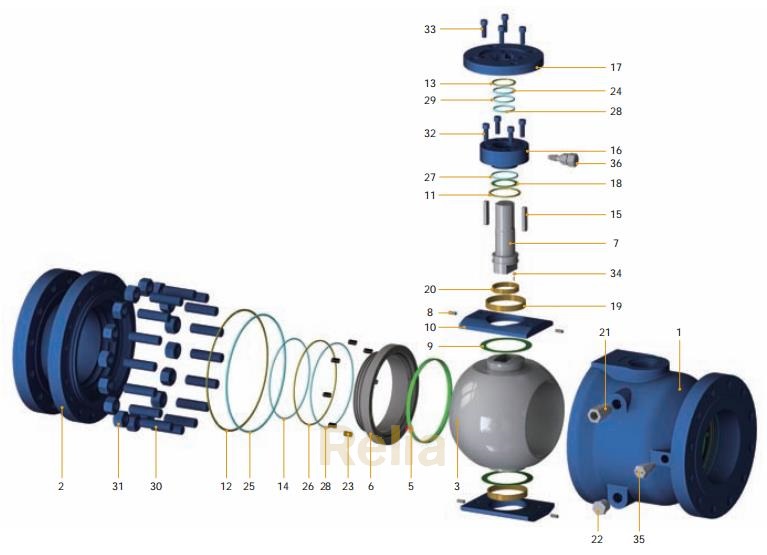

Explosive Drawing

Forged Steel Trunnion Mounted Ball Valve

Material Specifications

| No | Part | Standard | Stainless Steel | Sour Service | Low Temperature Service |

| 1 | Body | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 2 | Body cap | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 3 | Ball | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350 LF2/ENP |

| 4 | Seat Assembly(5+6) | 5&6 | 5&6 | 5&6 | 5&6 |

| 5 | Seat Insert | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK |

| 6 | Seat Ring | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350 LF2/ENP |

| 7 | Stem | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350 LF2/ENP |

| 8 | Trunnion | ASTM A182 F6a | ASTM A182 F316L | ASTM A182 F6a | ASTM A182 F6a |

| 9 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 10 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 12 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 13 | Fire Safe seal | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 14 | Top Flange | ASTM A105N | ASTM A182 F304 | ASTM A105N | ASTM A350 LF2 |

| 15 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 16 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 17 | Bearing | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 |

| 18 | Bearing | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE |

| 19 | Cover | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350 LF2 |

| 20 | Pin | Carbon Steel | Stainless Steel | Carbon Steel | Carbon Steel |

| 21 | Pin | Carbon Steel | Stainless Steel | Carbon Steel | Carbon Steel |

| 22 | Anti-Static Device | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 23 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 24 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 25 | O-Ring | NBR | NBR | NBR | NBR |

| 26 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 27 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 28 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 29 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 30 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 31 | Body Stud | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 32 | Body Nut | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7M |

| 33 | Screw | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 34 | Body Stud | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 35 | Body Nut | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7M |

| 36 | Screw | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

Cast Steel Trunnion Mounted Ball Valve

Material Specifications

| No | Part | Carbon Steel | Stainless Steel | Sour Service | Low Temperature Service |

| 1 | Body | ASTM A216-WCB | ASTM A351-CF8M | ASTM A216-WCB | ASTM A352-LCB |

| 2 | Body cap | ASTM A216-WCB | ASTM A351-CF8M | ASTM A216-WCB | ASTM A352-LCB |

| 3 | Ball | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350-LF2/ENP |

| 4 | Seat Assembly(5+6) | 5&6 | 5&6 | 5&6 | 5&6 |

| 5 | Seat Insert | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK | RPTFE/NYLON/PEEK |

| 6 | Seat Ring | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350-LF2/ENP |

| 7 | Stem | ASTM A105N/ENP | ASTM A182 F316 | ASTM A105N/ENP | ASTM A350-LF2/ENP |

| 8 | Trunnion Alignment Pin | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 9 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 10 | Trunnion Support | ASTM A588B/ENP | ASTM A351-CF3M | ASTM A588B/ENP | ASTM A588B/ENP |

| 11 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 12 | Gasket | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 13 | Fire Safe seal | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 14 | Fire Safe seal | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite | 316SS+Graphite |

| 15 | Key | Carbon Steel | Stainless Steel | Carbon Steel | Stainless Steel |

| 16 | Cover Flange | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350-LF2 |

| 17 | Top Flange | ASTM A105N | ASTM A182 F316 | ASTM A105N | ASTM A350-LF2 |

| 18 | Thrust Washer | PTFE | PTFE | PTFE | PTFE |

| 19 | Bearing | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 | 316SS+PTFE+MoS2 |

| 20 | Bearing | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE | 316SS+PTFE |

| 21 | Vent Valve | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 22 | Drain | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 23 | Spring | Inconel X-750 | Inconel X-750 | Inconel X-750 | Inconel X-750 |

| 24 | O-Ring | NBR | NBR | NBR | NBR |

| 25 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 26 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 27 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 28 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 29 | O-Ring | HNBR/VITON | HNBR/VITON | HNBR/VITON | HNBR/VITON |

| 30 | Body Stud | ASTM A193-B7 | ASTM A193-B8 | ASTM A193-B7M | ASTM A320-L7M |

| 31 | Body Nut | ASTM A194-2H | ASTM A194-8 | ASTM A194-2HM | ASTM A194-7M |

| 32 | Screw | ASTM A193-B7 | Stainless Steel | ASTM A193-B7M | ASTM A320-L7M |

| 33 | Screw | ASTM A193-B7 | Stainless Steel | ASTM A193-B7M | ASTM A320-L7M |

| 34 | Anti-Static Device | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 35 | Injection | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 36 | Injection | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)