How Does A Trunnion Ball Valve Work?

A trunnion ball valve is a type of quarter-turn ball valve, with its ball hold by a stem at the top and a stem at the bottom called trunnion. The ball will not shift even under high flow pressure, while the seats is “floating” under pressure.

When the valve is in the open position, the fluid flows through the valve body and around the ball. The ball is held in the open position by the stem, which is connected to the actuator. The actuator rotates the stem, which in turn rotates the ball. When the ball is rotated 90 degrees, it blocks the flow of fluid and the valve is closed.

How does the trunnion ball valve block the fluid?

Under low fluid pressure conditions:

The sealing principle of trunnion ball valves under low pressure conditions is mainly achieved through the pre-tightening force between the valve seat and the valve ball. When the valve is in closed position, the valve seat is tightly pressed against the surface of the ball under the action of medium pressure and spring force, forming a reliable seal. This design ensures good sealing performance even under low or no pressure conditions.

Under high fluid pressure conditions:

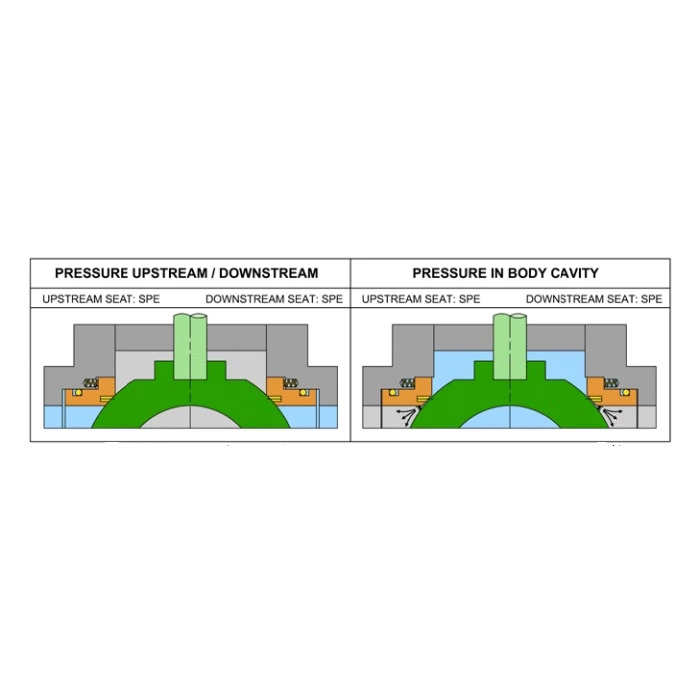

The flow pressure pushes the seat to force the seat to closely contact the ball to ensure the seal. Trunnion mounted ball valve are equipped with a floating seat. After being pressured by the medium, the seat will move towards to seat so that the sealing ring is pressed tightly on the ball to ensure the sealing.

Key Parts:

- Stem – A shaft connected to the actuator or handle that rotates the ball.

- Ball – A spherical disc with a bore (hole) through the center that allows or blocks flow.

- Trunnion Mounting – The ball is supported by two trunnions (short shafts) at the top and bottom, which are fixed to the valve body. This prevents the ball from floating under pressure.

- Seats – Resilient (often polymer) or metal sealing rings that ensure tight closure when the valve is shut. Stem – A shaft connected to the actuator or handle that rotates the ball.

- Body & Bonnet – The main housing that contains all internal components.

- Seals – O-rings and gaskets made from materials compatible with the media and operating conditions are used to prevent leakage between different valve components.

Advantages Over Floating Ball Valves:

- Better for high-pressure applications – Trunnion support prevents seat deformation.

- Lower operating torque – The ball doesn’t shift under pressure, making it easier to operate.

- Larger sizes possible – Commonly used in pipelines 6" and above.

- Double Block & Bleed (DBB) capability – Each seat block the fluid from each side, with self-relieving seat; Some trunnion valves allow isolation and venting between seats.

Common Applications:

- Oil & gas pipelines

- High-pressure steam systems

- Chemical processing

- Water transmission (large-diameter)