Cavity Pressure Relief Trunnion Ball Valve

Automatic cavity-pressure relief trunnion ball valve shall be consided, if liquid or multi-phase fluid trapping is possible. Normally, the valve cavity relief shall not exceed 33% differential pressure above the valve pressure rating.

For design temperature up to 250 °F (121 °C) the valve cavity relief shall not exceed 33% differential pressure above the valve pressure rating.

Relief pressures for design temperatures above 250°F (121°C) will be specified by us.

To achieve a higher cavity relief pressure, the valve shell shall be designed and tested to withstand a higher hydrostatic shell test pressure.

External cavity relief valves shall be NPS ½ (DN 15) or larger.

If a relief valve fitted to the cavity is required, purchaser may specify provisions to facilitate in service testing

Cavity Relief Testing

I.9.1 General

If the valve has one or more self-relieving seats or a relief system that connects the valve cavity to one side of the valve, the test shall conform to a documented procedure, by agreement.

Each valve shall be tested except valves that cannot trap pressure in the cavity.

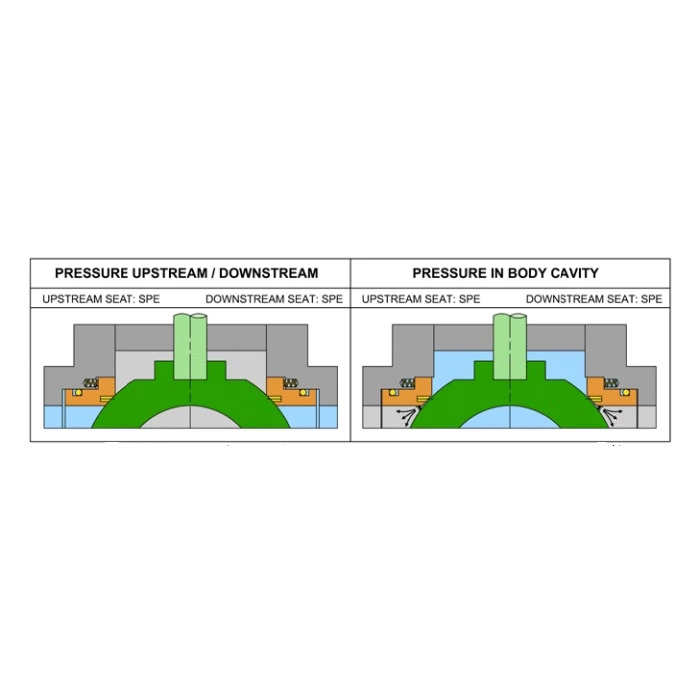

For valves where cavity overpressure relief is provided via one or more self-relieving seats, this shall be demonstrated by one of the cavity relief tests in I.9.2.

For trunnion-mounted ball valves with self-relieving seats, selection of one of the three procedures of in I.9.2 shall be by agreement.

I.9.2 Trunnion-mounted Ball Valves

I.9.2.1 Procedure 1—Internal Relieving Seats

The procedure for cavity-relief testing of trunnion-mounted ball valves with internal-relieving seats shall be as follows:

a) Fill the valve in the half-open position with hydrostatic test fluid and purge trapped air

b) Close the valve

c) Close the branch vents

d) Apply pressure to the valve cavity until one branch pressure starts to rise and the seat relieves the cavity pressure into the valve end; record this relief pressure and port location.

For valve types with two self-relieving seats, continue to increase the pressure to the cavity until the second branch pressure starts to rise and the second seat relieves; record the relief pressure of the second seat.

Failure to relieve at differential pressure less than 33 % of the valve pressure rating shall be cause for rejection.

EXAMPLE 1 Class 150, 275 psi (19.0 bar), the maximum rated pressure-relief pressure is 90 psi (6.2 bar).

EXAMPLE 2 Class 2500, 6250 psi (430.9 bar), the maximum rated pressure-relief pressure is 2060 psi (142.1 bar).

Failure to relieve pressure shall be cause for rejection.

Pressure–temperature ratings for class-rated valves shall conform to the applicable rating table for the appropriate material group in ASME B16.34 or MSS-SP 44.

I.9.2.2 Optional Procedure 2—One or More Self-relieving Seats

The procedure for cavity-relief testing of trunnion-mounted ball valves with one or more self-relieving seats shall be conducted using the following.

a) Fill the valve in the half-open position with hydrostatic test fluid.

b) Close the valve.

c) Pressurize both sides of the valve and the valve cavity simultaneously, up to 1.0 times rated working pressure (RWP).

d) Isolate both sides of the valve and the valve cavity from pressure source.

e) Slowly decrease pressure on one side while monitoring the valve cavity pressure. Record pressure on that side required to activate SPE seat seal relief (point at which valve cavity pressure decreases).

f) Repeat Steps a) to d) for the other side if it has a self-relieving seat.

Failure to relieve at a differential pressure less than 33% the valve pressure rating over the valve pressure rating shall be cause for rejection.

Pressure–temperature ratings for class-rated valves shall conform to the applicable rating table for the appropriate material group in ASME B16.34 or MSS-SP 44.

I.9.2.3 Procedure 3—Relief System Connecting Valve Cavity to One Valve Side

The procedure for cavity-relief testing of trunnion-mounted ball valves with a relief system that connects the valve cavity to one side of the valve shall be as follows:

a) Fill the valve in the half-open position with hydrostatic test fluid and purge trapped air

b) Close the valve

c) Close the branch vents

d) Apply pressure to the valve cavity until one branch pressure starts to rise; record this relief pressure and port location

Failure to relieve at differential pressure less than 33 % of the valve pressure rating shall be cause for rejection.

EXAMPLE 1 Class 150, 275 psi (19.0 bar), the maximum rated pressure-relief pressure is 90 psi (6.2 bar).

EXAMPLE 2 Class 2500, 6250 psi (430.9 bar), the maximum rated pressure-relief pressure is 2060 psi (142.1 bar).

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)