Fully Welded Trunnion Ball Valve

Fully welded trunnion ball valve features a forged steel body; the welded construction avoids potential leak paths to the external environment, ensuring reliable protection of the pipeline.

Relia fully welded trunnion ball valves are mainly used in gas transmission and distribution pipelines (mid-stream), typical for underground and buried installations.

- Full welded body, with NDT examination on welding joint

- Double block and bleed design (DBB)

- Secondary seals in pure Graphite

- Anti-static device

- Anti-blowout stem

- Emergency sealant injection on seats and stem available

- Low fugitive emission stem packing available

- CRA overlay on all dynamic sealing areas or on all wetted parts available

- Stem extension for underground installations

TEMPERATURE RANGE

- -150 to 428°F (-101 to 220°C)

SIZE

- NPS 2-56 (DN 50-1400)

PRESSURE RATING

- ASME 150 - ASME 2500

FACE-TO-FACE

- As per API 6D standard

END CONNECTIONS

- RF, RTJ as per B16.5 &B16.47

- BW, Butt Welded as per B16.25

BODY DESIGN

- Forged welded two-piece and three-piece

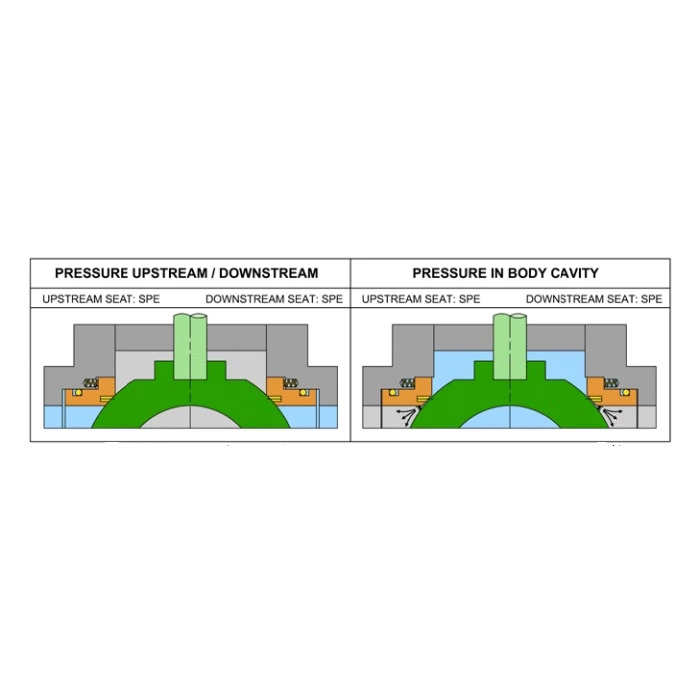

SEAT DESIGN

- Soft or metal seated with hard facing on Ball and Seats

- Self relieving seats

- Double piston seats

FEATURES

- Double block and bleed design (DBB)

- Secondary seals in pure Graphite

- Anti-static device

- Anti-blowout stem

- Emergency sealant injection on seats and stem available

- Low fugitive emission stem packing available

- CRA overlay on all dynamic sealing areas or on all wetted parts available

- Stem extension for underground installations

OPERATOR

- Manual: wrench or gear with padlocking

- Actuated: Pneumatic/ Hydraulic/Electric

TESTING & CERTIFICATIONS

- Compliance with API 6D & ISO 5208 & API 598 inspection and testing

- The valve body (forged steel) is subjected to Ultrasonic test of critical areas and BW ends (50 mm).

- The welded joint between body and bonnet are Dye-penetrant inspected at 100%.

- Fire safe and fire tested as per API 6FA/607

- SIL 3 Certification as per IEC61508

- Fugitive Emission as per ISO15848

- PED 2014/68/UE

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)