Welded Body Trunnion Ball Valve

Welded body trunnion ball valves are made of forged steel with their body of valve constructed by welding of all parts except stem housing to avoid the risk of external leakage.

The body-neck are welded by experienced and qualified workers with advanced welding machine and post weld heat treatment is to be done after that to relieve the stress.

Full Welded Ball Valves are designed for above and underground applications in natural gas and crude-oil pipelines transportation, distribution and storage systems as on / off valves. They are Generally used between-46°C up to 100°C.

Fully Welded Body

Full welded design can prevent external leakage and provide maintenance free long service life.

Welding is the core of the entire production process of welded body ball valve, which directly determines the service life of valves. The welding uses submerged arc automatic welding, combined with argon arc welding as the base. The temperature in the operating room should be controlled between 15-25 degrees Celsius, and the humidity should not exceed 60%. The welding are operated by qualified welders. The welding slag must be knocked off and carefully inspected when each weld is completed. Key areas such as the connection between the valve body and flange require 100% X-ray inspection. If any air holes are found, they should be repaired immediately.

Trunnion Mounted Ball

Trunnion mounted ball valves have additional anchoring at the top and the bottom of the ball. Those two trunnions absorb the thrust generated by the line pressure, preventing excess friction between the ball and seats. Therefore, operating torques stay low, even at full working pressures.

Stem Sealing

The sealing of the stem to the atmosphere is achieved by three independent sealing systems.The stem sealing design ensures the anti-blow-out function, too. Therefore, certain stem sealings are easily replaceable under full line pressure in open or closed position.

Seat Sealing

Fully welded ball valves are equipped with soft, metallic or PMSS (Primary Metal Secondary Soft) seat rings for specific applications. Our ball valves also have spring-loaded seat rings as standard, which ensure a tight seal even with the lowest line pressures.

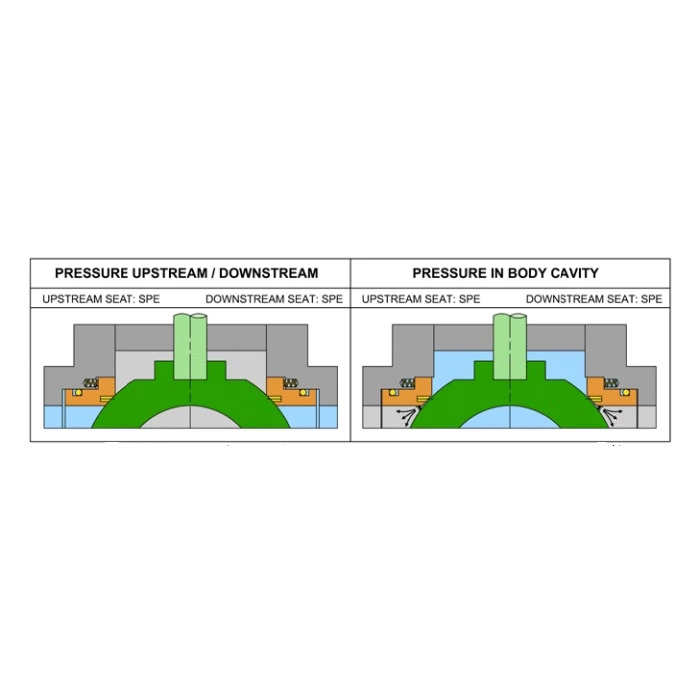

Double Block and Bleed

This enables the verification of the tightness of the ball valve under full working pressure.

The upstream and downstream seat rings ensure the tight shut off to the cavity in closed and open position as well.

For the leak test, the cavity is emptied through a vent valve. If no medium flows in after draining, the tightness has been verified.

Emergency Sealing

As an option, fully welded body trunnion ball valves can be delivered with an additional emergency sealant injection for the seat-rings and stem sealing.

Fire Safe Design

To limit leakage in case of fire, our valves are provided with a secondary seal, metallic or graphite based, in all the sealing points. Fire tests according to API 607, API 6FA and EN ISO 10497 have already been performed to certify the entire range of valves.

Anti-blowout Stem

As a safety feature, the valve is designed to avoid the blowout of the stem during the disassembly of the packing when pressure is trapped in the body cavity.

Anti-static Device

To avoid any dangerous effects caused by static electricity charges, all Relia ball valves incorporate an anti-static device to keep electric continuity between body, stem and ball. This is generally achieved by using springs (stem and/or trunnion to ball) or spring energized balls (stem to body).

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)