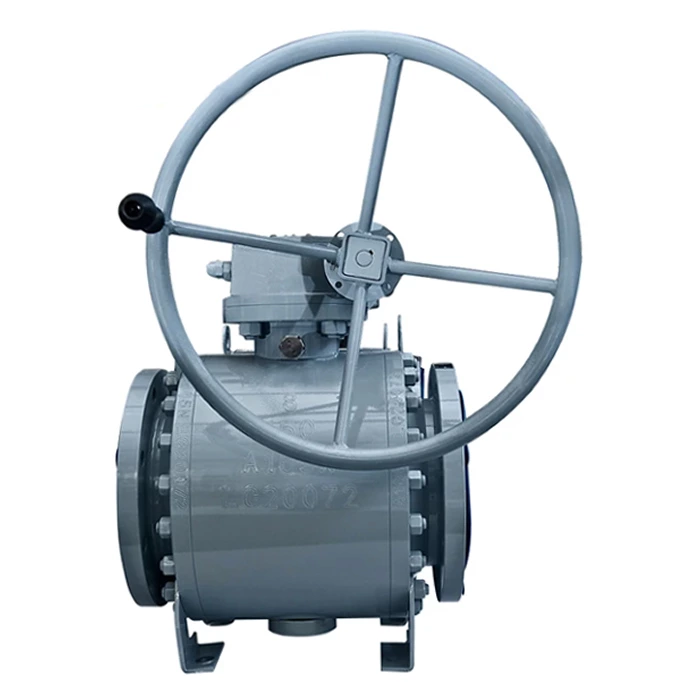

Side Entry Trunnion Ball Valve

A side-entry trunnon ball valve is a type of trunnon-mounted ball valve where the ball is assembled from the side.

The body construction comes in 2 piece or 3-pieces split body depending on the size and class.

Side-entry trunnion ball valves are the standard ball valve type and should be the default choice for general service.

- Design Feature

- Side entry, Split body, 2 piece or 3 piece body

- Ball Type

- Trunion Mounted Ball Valve

- Size

- 2"-48"

- Pressure Rating

- Class 150-2500

Features and Benifit

Their split-body 2 pieces or 3 pieces design makes side entry trunnion ball valves easier to install in existing piping systems. This construction also allows for greater flexibility during initial assembly and integration.

Material Versatility

Side entry trunnion ball valves offer flexibility in material selection for different components, such as the body, ball, and seats. This adaptability allows customization to meet specific application needs, such as corrosion resistance or cost optimization.

Compact Horizontal Design

The horizontal assembly of side entry trunnion ball valves results in a smaller footprint, making them suitable for installations where vertical space is limited.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)