When making an inquiry or ordering a trunnion ball valve, the following information should be included: valve size, pressure rating, body type, seat structure, end connection, operators, body material, and trim material.

Valve Size

Full Bore Valve

| Inch |

2 |

2-1/2 |

3 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

| Inch |

26 |

28 |

30 |

32 |

37 |

36 |

38 |

40 |

42 |

46 |

48 |

54 |

56 |

60 |

| mm |

650 |

700 |

750 |

800 |

850 |

900 |

950 |

1000 |

1050 |

1150 |

1200 |

1350 |

1400 |

1500 |

Reduced Bore Valve

| Inch |

2x1-1/2 |

3x2 |

4x3 |

6x4 |

8x6 |

10x8 |

12x10 |

14x10 |

16x12 |

| mm |

50x40 |

80x50 |

100x80 |

150x100 |

200x150 |

250x200 |

300x250 |

350x250 |

400x300 |

| Inch |

18x14 |

20x16 |

22x18 |

24x20 |

26x20 |

28x24 |

30x24 |

32x26 |

34x28 |

| mm |

450x350 |

500x400 |

550x450 |

600x500 |

650x500 |

700x600 |

750x600 |

800x650 |

850x700 |

| Inch |

36x30 |

38x32 |

40x34 |

42x36 |

46x40 |

48x42 |

54x42 |

56x48 |

60x48 |

| mm |

900x750 |

950x800 |

1000x850 |

1050x900 |

1150x1000 |

1200x1000 |

1350x1050 |

1400x1200 |

1500x1200 |

Pressure Rating

| ANSI Class |

150 |

300 |

400 |

600 |

800 |

900 |

1500 |

2500 |

| PN |

20 |

50 |

68 |

100 |

135 |

160 |

260 |

420 |

| Symbol |

1 |

3 |

4 |

6 |

8 |

9 |

15 |

25 |

Body Type

| Symbol |

Body Type |

| SB |

Side Entry, Bolted Body |

| SW |

Side Entry, Welded Body |

| TB |

Top Entry, Bolted Body |

Seat Structure

| Symbol |

Seat Structure |

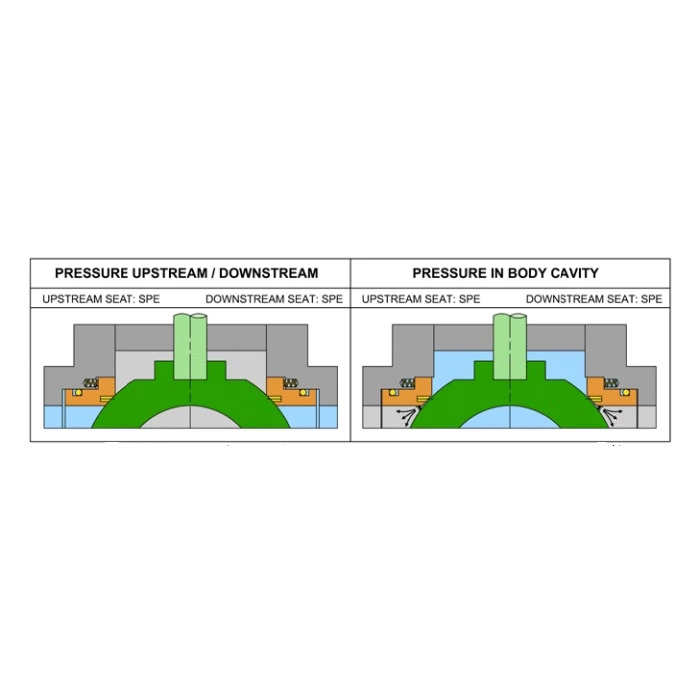

| DBB |

Double Block and Bleed |

| DIB 1 |

Double Isolation and Bleed Type 1 |

| DIB 2 |

Double Isolation and Bleed Type 2 |

End Connections

| Symbol |

End |

| R |

Raised face flanged end |

| J |

RTJ flanged end |

| B |

Butt-weld end |

| HB |

Hub |

Valve Operators

| Symbol |

Description |

Symbol |

Description |

| L |

Lever |

BS |

Bare shaft |

| G |

Gearoperator |

H |

Hydraulic actuator |

| M |

Electric actuator |

L |

Gas over oil actuator |

| P |

Pneumaticactuator |

D |

Electric over oil actuator |

Body Material

| Steel Classification |

Cast Material |

Forging Material |

Recommended Temperature Limits |

Application |

| ℃ |

℉ |

| Carbon Steel |

A216 WCB |

A105N |

-29 to 425 |

-20 to800 |

Steam, water oil, oil vapour,

gas and general service |

| Carbon Steel |

A352 LCB |

A350 LF2 |

-46 to350 |

-50 to650 |

Low temperature |

| Carbon Steel |

A352 LCC |

A350 LF2 |

-46 to 350 |

-50 to 650 |

| Duplex Stainless Steel |

A995 4A |

A182 F51 |

-51 to 315 |

-60 to 599 |

Corrosion resistance |

| Duplex Stainless Steel |

A995 5A |

A182 F53 |

-51 to 315 |

-60 to 599 |

| Austenitic Stainless Steel |

A351 CF8M |

A182 F316 |

-196 to 815 |

-320 to 1500 |

High and low temperature

corrosion resistance.

Cryogenic service is

also available upon request. |

| Austenitic Stainless Steel |

A351 CF8 |

A182 F304 |

-196 to 815 |

-320 to 1500 |

| Low Carbon Stainless Steel |

A351 CF3M |

A182 F316L |

-196 to 815 |

-320 to 1500 |

| Low Carbon Stainless Steel |

A351 CF3 |

A182 F304L |

-196 to 815 |

-320 to 1500 |

Trim Material

| Seat Insert |

O-ring |

Stem |

Ball |

Seat |

| Code |

Material |

Code |

Material |

Code |

Material |

Code |

Material |

Code |

Material |

| 1 |

PTFE |

1 |

NBR |

1 |

F6a |

1 |

F6a |

1 |

F6a |

| 3 |

PEEK |

2 |

VITON A |

2 |

F304 |

2 |

F304 |

2 |

F304 |

| 5 |

DEVLON V |

3 |

VITON AED |

3 |

A105N/ENP |

3 |

A105N/ENP |

3 |

A105N/ENP |

| 7 |

NYLON 12 |

4 |

VITON B |

4 |

17-4PH |

4 |

17-4PH |

4 |

17-4PH |

| 8 |

PCTFE |

6 |

HNBR |

5 |

AISI 4140/ENP |

5 |

AISI 4140/ENP |

5 |

AISI 4140/ENP |

| L |

Lipseal |

8 |

VITON GLT |

6 |

F316 |

6 |

F316 |

6 |

F316 |

| L |

HNBR |

V |

FEPM |

7 |

F304L |

7 |

F304L |

7 |

F304L |

| J |

VITON |

L |

Lipseal |

8 |

F316L |

8 |

F316L |

8 |

F316L |

| |

|

|

|

9 |

LF2/ENP |

9 |

LF2/ENP |

9 |

LF2/ENP |

| |

|

|

|

A |

F51 |

A |

F51 |

A |

F51 |