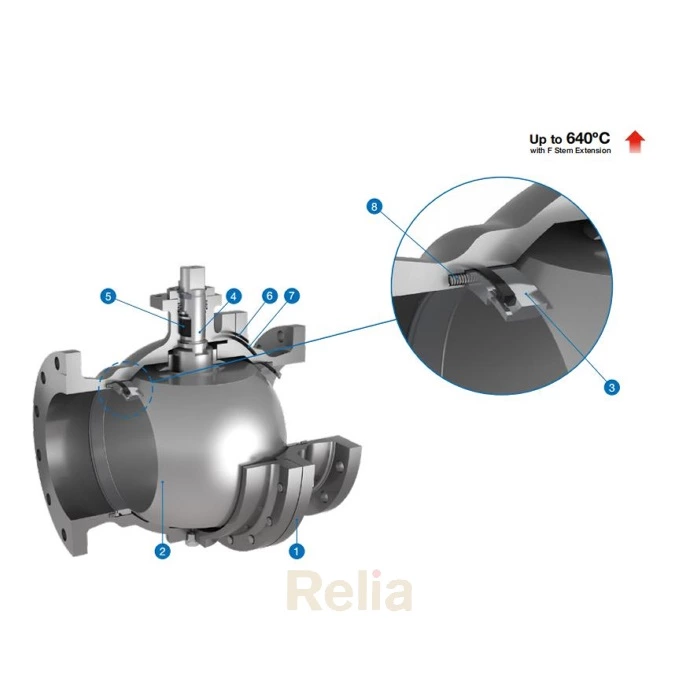

Metal Seated Trunnion Ball Valve

Metal-seated trunnion ball valves for different services (slurries, pulp and liquors, high temperatures, abrasive or sticking fluids, control) are tested for bubble tight sealing.

- Bubble-tight sealing up to 327°C and Class V up to 500°C

- Low coefficient of friction

- Excellent sliding and running properties

- Hardens the complete surface of the ball and seats

- Size

- 2"-24"

- Pressure Rating

- Class 150-2500

- Temperature Range

- -29~640℃

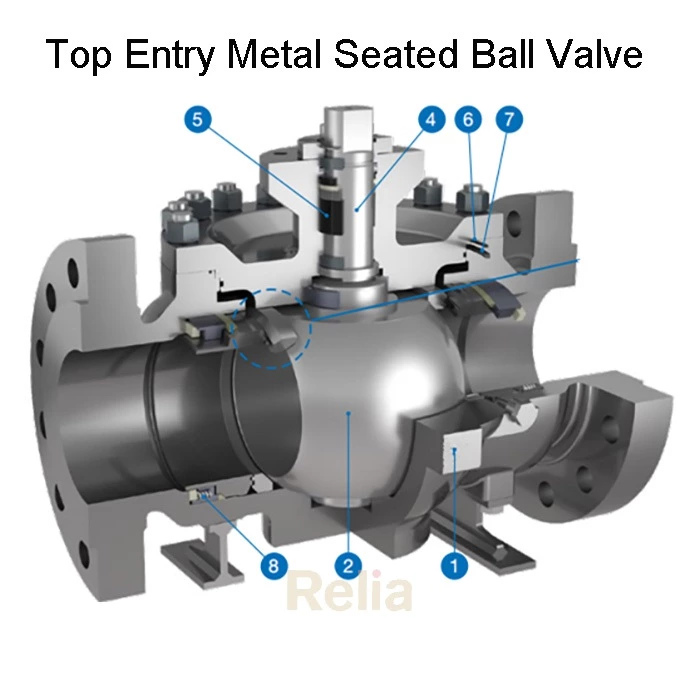

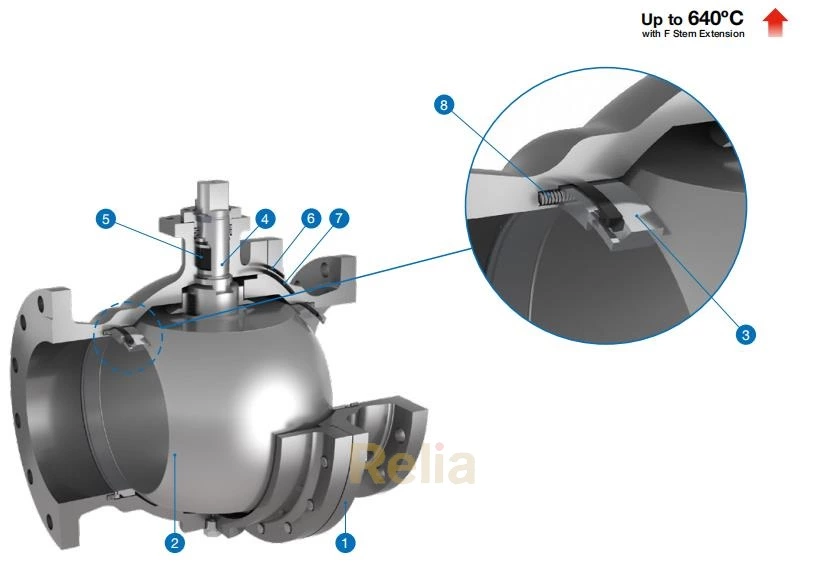

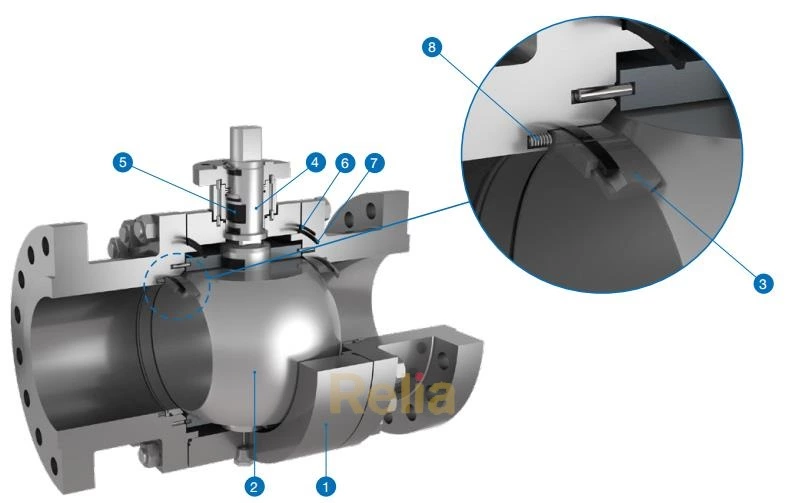

Metal Seated Trunnion Ball Valve Drawing

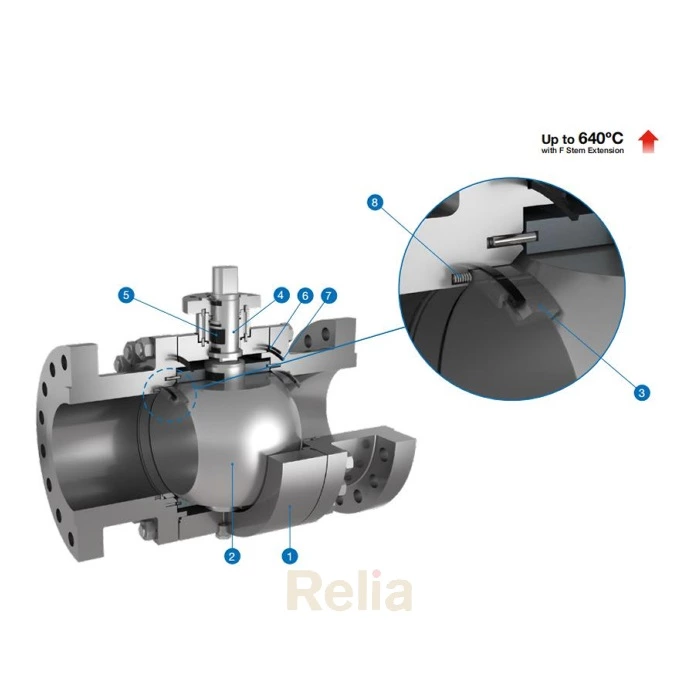

Cast Steel Metal Seated Trunnion Ball Valve

Forged Steel Metal Seated Trunnion Ball Valve

Standard Material

| Part No. | Part Name | ANSI* | DIN* | ||

| Carbon steel | Stainless steel | Carbon steel | Stainless steel | ||

| 1 | Body | A105/A350 LF2 | A182 F316 | 1.0352 | 1.4401 |

| 2 | Ball | F316+TCC/CCr/HCr/Stellite | 1.4401+TCC/CCr/HCr/Stellite | ||

| 3 | Seats | F316+TCC/CCr/HCr/Stellite | 1.4401+TCC/CCr/HCr/Stellite | ||

| 4 | Stem | XM-19 | XM-19 | ||

| 5 | Stem packing | Graphite | Graphite | ||

| 6 | Body seal 1 | Graphite | Graphite | ||

| 7 | Body seal 2 | Graphite | Graphite | ||

| 8 | Spring Seat | Inconel X-750 | Inconel X-750 | ||

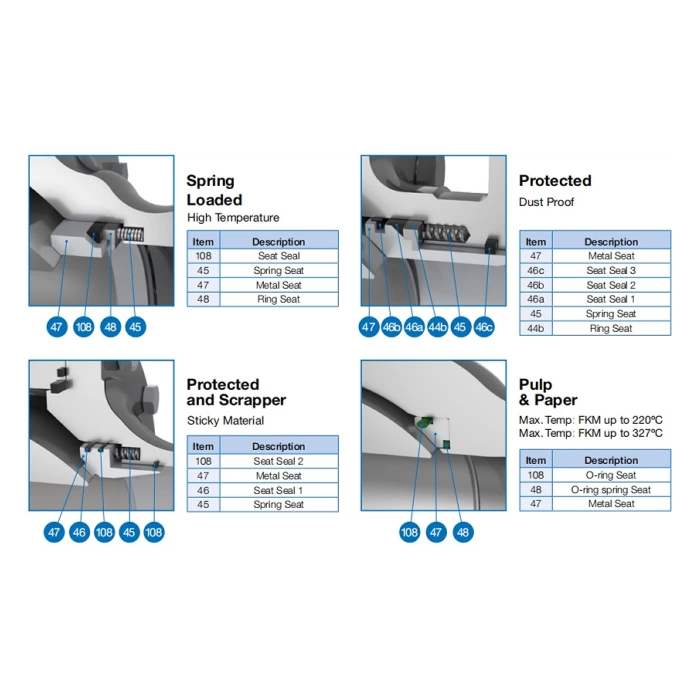

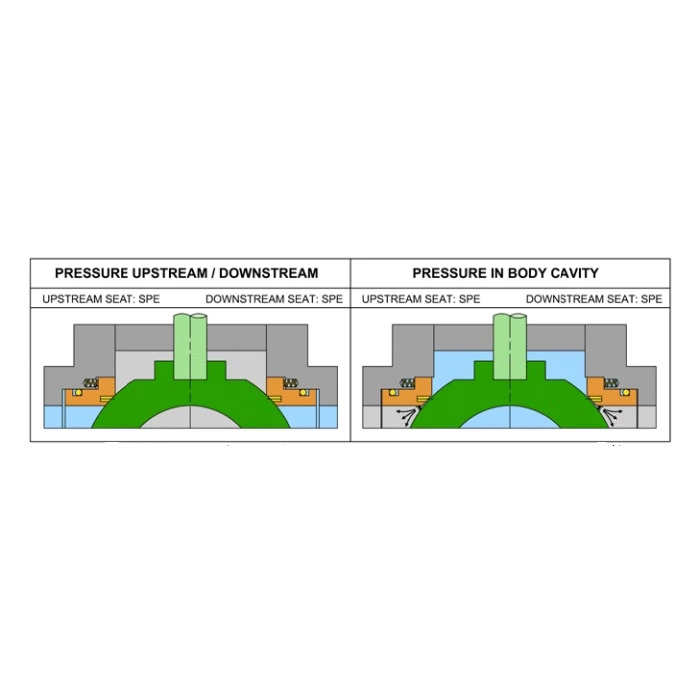

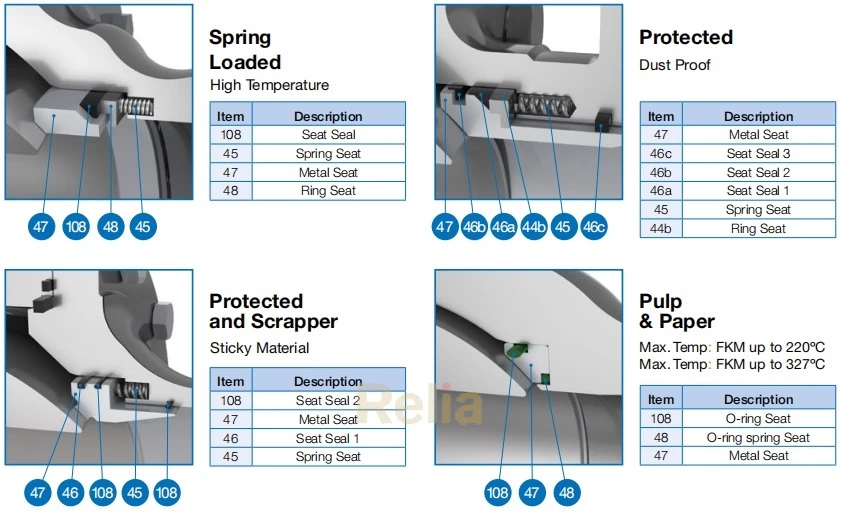

Seat Types

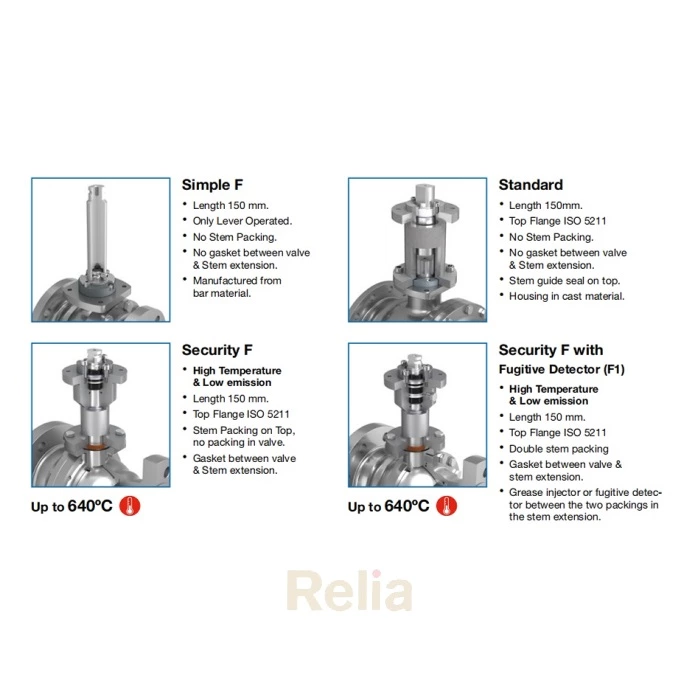

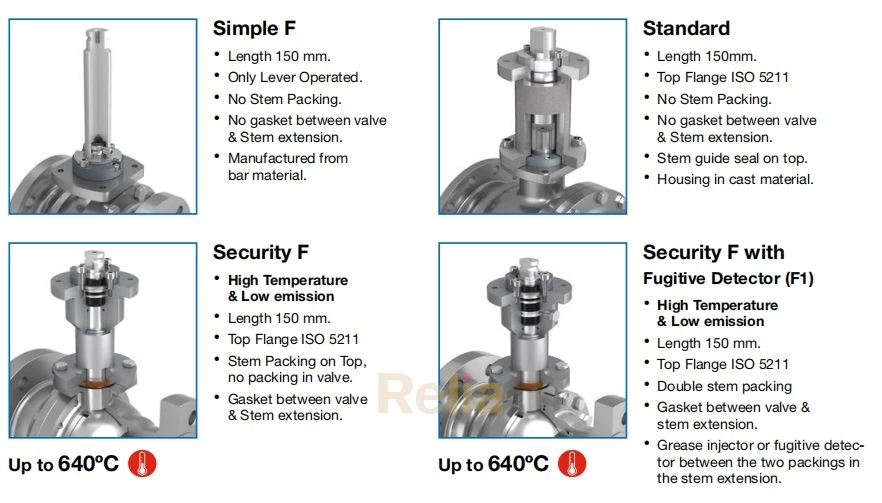

Stem Extensions

COATING MATERIALS

Chrome Carbide (CrC)

Chrome carbide is the standard coating for Relia ball valves, is well suited to very high-temperature gas or liquid applications, and has excellent resistance to wear, erosion, and corrosive media. It has certain limitations in chlorine services and wet sulfur.

Hard Chromium (HCr)

Hard chromium is suited to a wide range of applications in liquids and gases. It is limited to moderate pressures and temperatures. HCr is not suitable for strong acids and fluids with high chloride content.

Tungsten Carbide (WC-Co)

Tungsten carbide is very resistant to wear and erosion from slurries, powders, and muds. It works well in cryogenic applications, hydrocarbon gases and liquids, oxygen, and dry gas services. It has limitations in terms of corrosive services and condensates.

Cobalt-Based Alloy

Cobalt-based coatings (Stellite) provide excellent mechanical wear resistance, superior corrosion resistance, and good performance at high temperatures (up to 535 °C). Stellite is used in a lot of applications in the pulp and paper industries and in refining applications.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)