Floating Ball Valve Vs Trunnion Ball Valve

Floating ball valve and trunnion ball valve differs in sealing mechanism, size & pressure application, cost and torque value etc.

1. Basic Comparation

| Feature | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Ball Support | Single upper stem; no lower support. Ball moves axially under fluid pressure to seal against the downstream seat. | Dual stems (upper and lower trunnions) fix the ball’s position. The ball remains stationary, while seats move to create a seal. |

| Force Transmission | Fluid pressure pushes the ball against the seat (“ball moves, seat fixed”) . | Fluid pressure pushes floating seats against the fixed ball (“ball fixed, seats move”). |

| Complexity | Simpler design, fewer components. | More complex with additional bearings, springs, and dual stems. |

| Torque Value | Higher | Lower |

| Cost | Lower | Higher |

Floating Ball Valve

2. Sealing Mechanism

- Floating Ball Valve:

- Single-sided sealing: Relies on downstream pressure to force the ball against the seat. Vulnerable to seat deformation in high-pressure/large-bore applications.

- Weakness: High fluid pressure may crush the seat or increase operating torque.

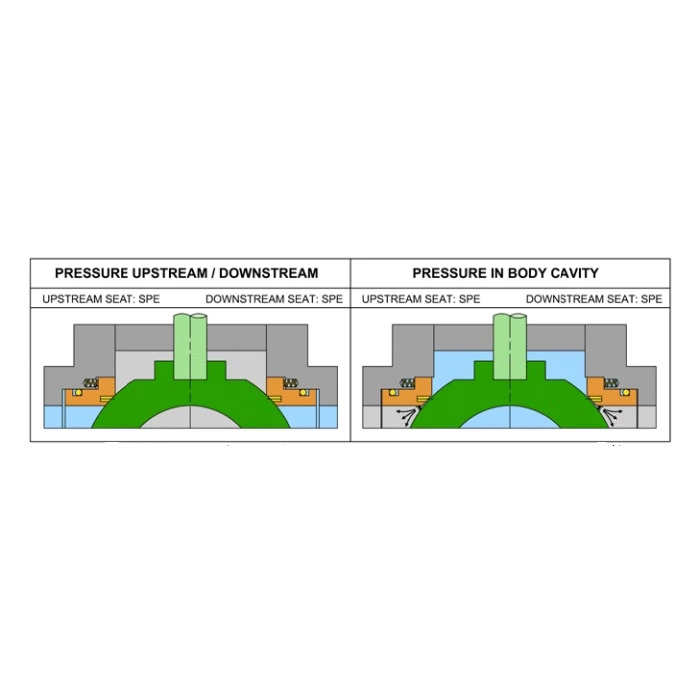

- Trunnion Ball Valve:

- Double-sided sealing: Spring-loaded floating seats on both sides create bidirectional seals. Seats compensate for wear via spring force.

- Pressure handling: Seals withstand higher pressures (Class 150–2500 per ASME) without seat damage.

3. Size Application

| Parameter | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Size & Pressure Rating | Class 150: 1/2"- 6" Class 300: 1/2"-4" Class 600: 1/2"- 3" Class 900: 1/2"- 2" Class 1500: 1/2"-1-1/2" |

Class 150: 4"- 48" Class 300: 3"- 48" Class 600: 2"- 40" Class 900: 2"- 36" Class 1500: 2"-24" Class 2500: 1-1/2"-12" |